Our solutions for maintenance applications

- Solder pallet and wave soldering machine parts,

- Reflow oven filters and parts,

- Conformal coating carriers,

- Pick and place SMT nozzles.

Solder or conformal coating pallets and oven filters cleaning process are a very difficult, tedious and dirty operation. MBtech has especially developed its MC200 process for you.

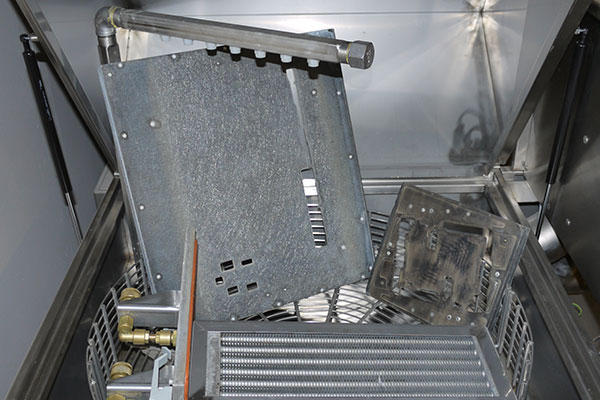

Very robust, easy to use and requiring only a minimum amount of monitoring, this cleaning process uses three direction spray arms combine to a heavy duty rotating basket. The MC200 will provide a perfect cleaning in a very short cycle even for over baked flux on oven filters.

The use of an adapted water-based chemical and the efficiency of our hot air drying system allows us to avoid a water rising step. Therefore, running cost as well as environmental impact are both extremely low.

For specific applications where a water rinse step is required, our MC200+ model will meet this particular requirement.

If your cleaning application requires an immersion process our MC10 will be the suitable answer.